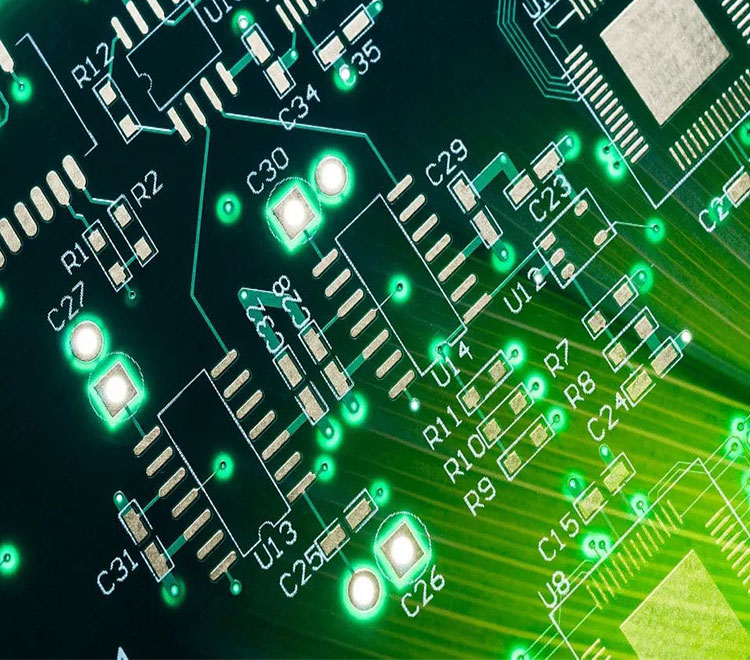

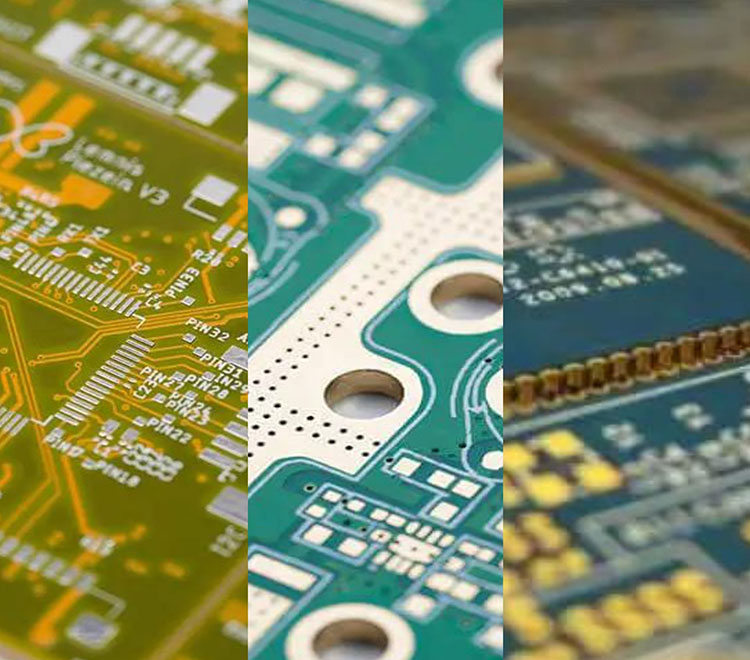

There is a wide range of PCB manufacturing services offered by GreensTone. We specialize in manufacturing kinds of PCBs such as FR4 PCB, heavy copper PCB, HDI PCB, China High-TG PCB, multi-layer PCB, rigid PCB and etc.

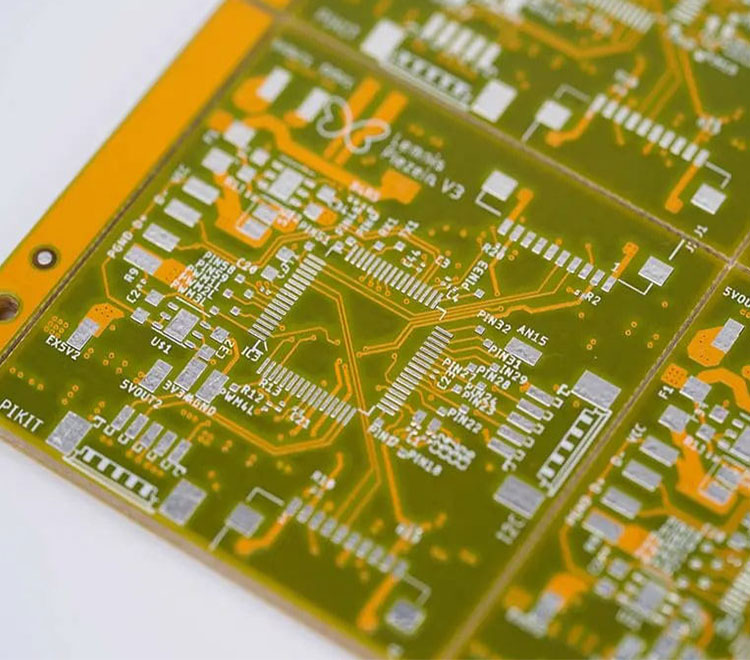

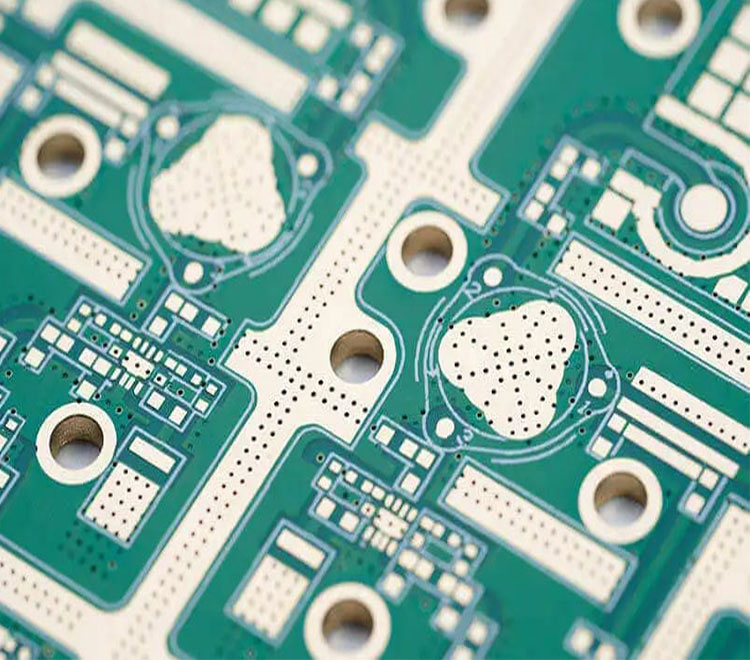

PCB is the abbreviation of the printed circuit board. PCB composed by insulated baseboard, pads for electronic components and copper foil connecting wires. PCB can replace complex wiring to achieve circuit connection between components in the circuit.

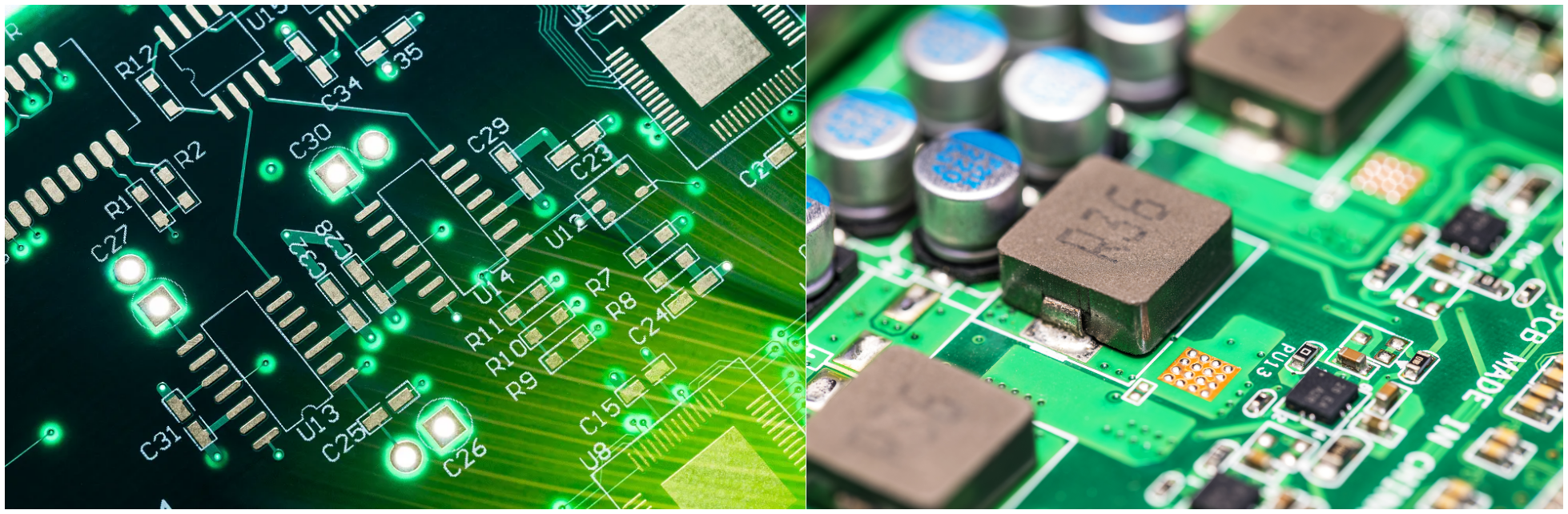

PCB is the motherboard of electronic components. Before the advent of PCB, the interconnection between electronic components was done directly by wires. Today, PCB has been widely used in the electronics industry, due to the PCB tecnology, manual wiring errors can be avoided, and electronic components can be automatically DIP or SMT pcb assembly, automatic soldering, and automatic detection, ensuring the quality of electronic device and improving labor productivity, reduce costs as well.

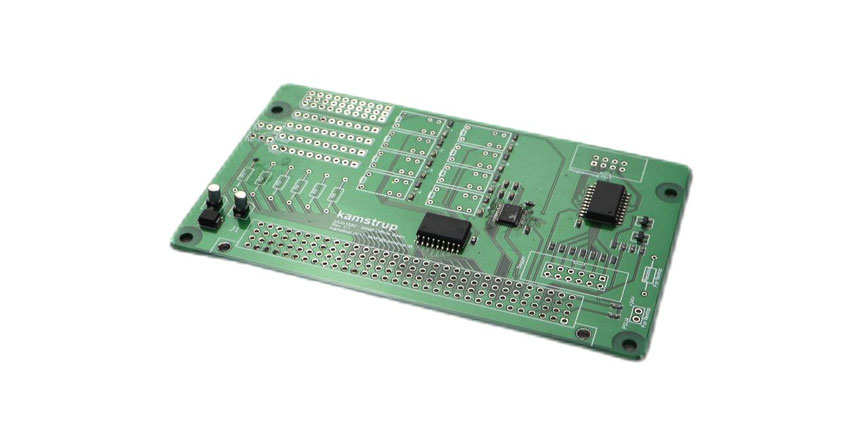

PCB is a blank circuit board without any electronic components soldered on. It just composed by baseboard with pads and copper foil connection wires.

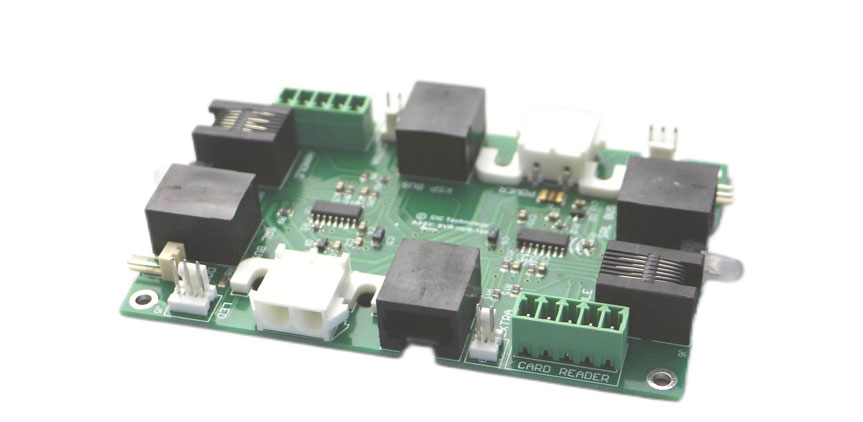

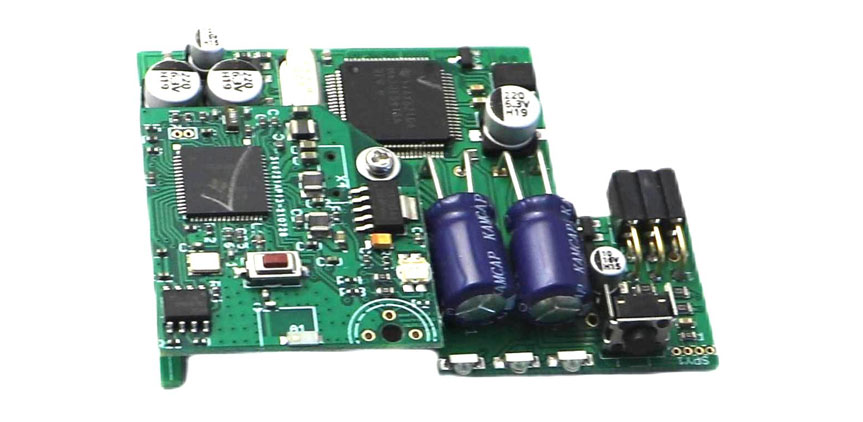

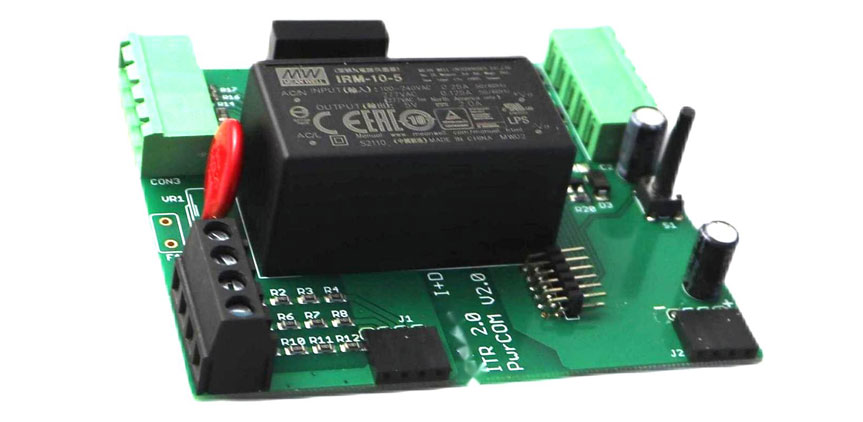

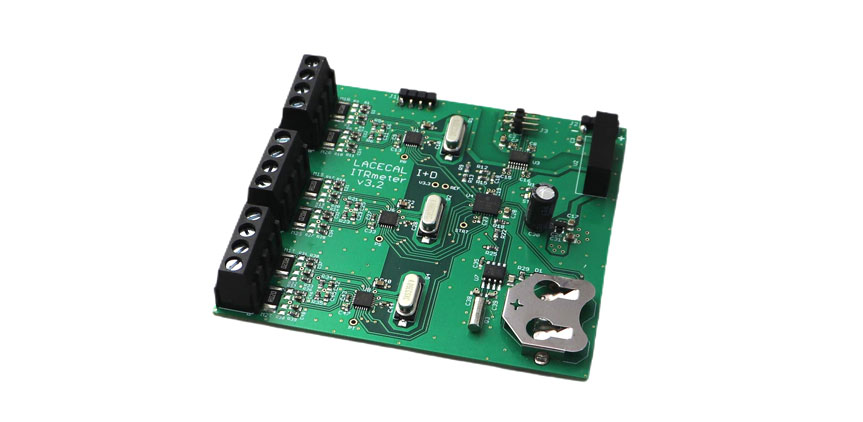

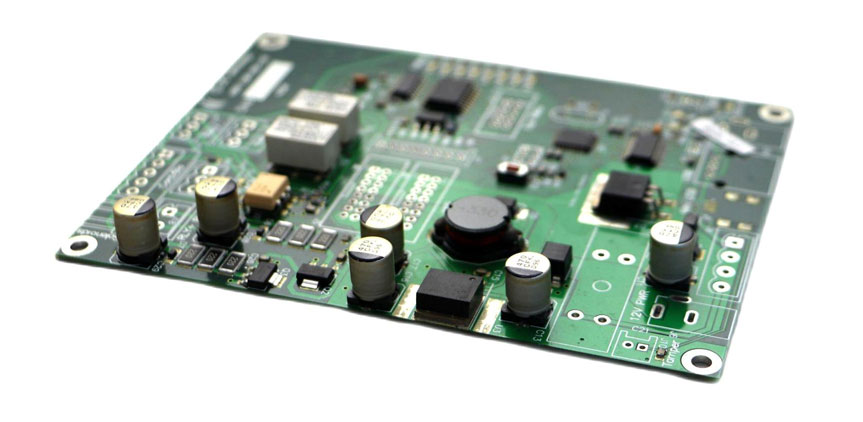

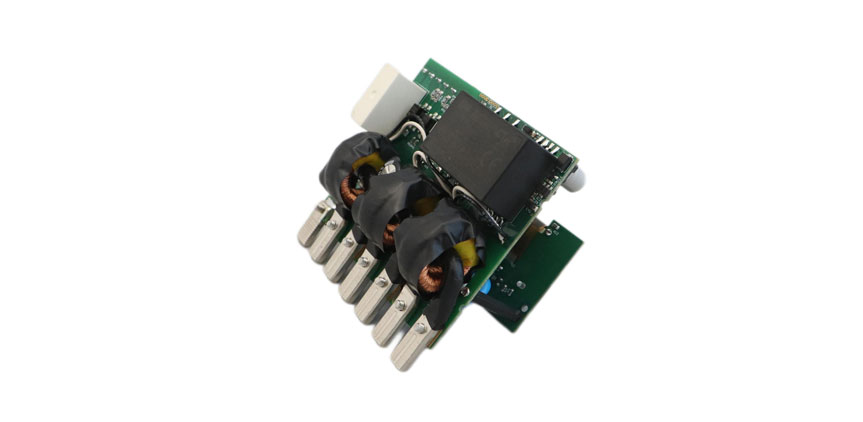

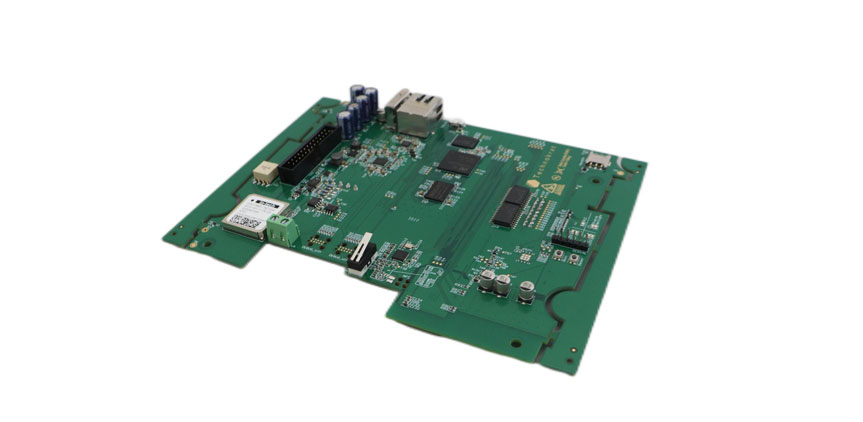

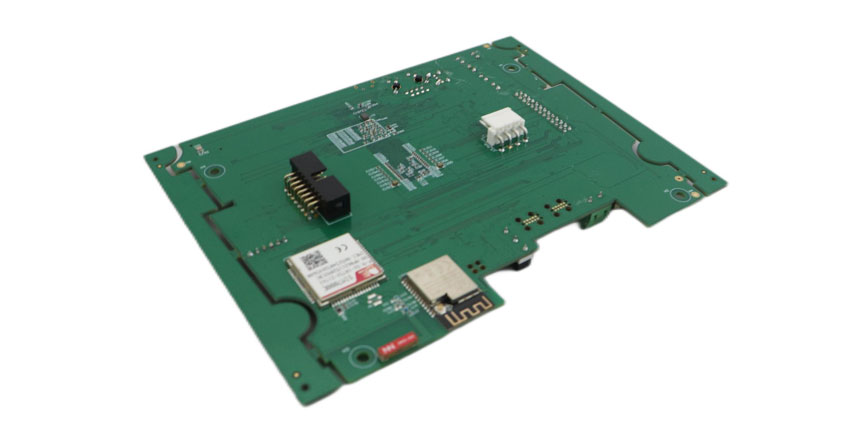

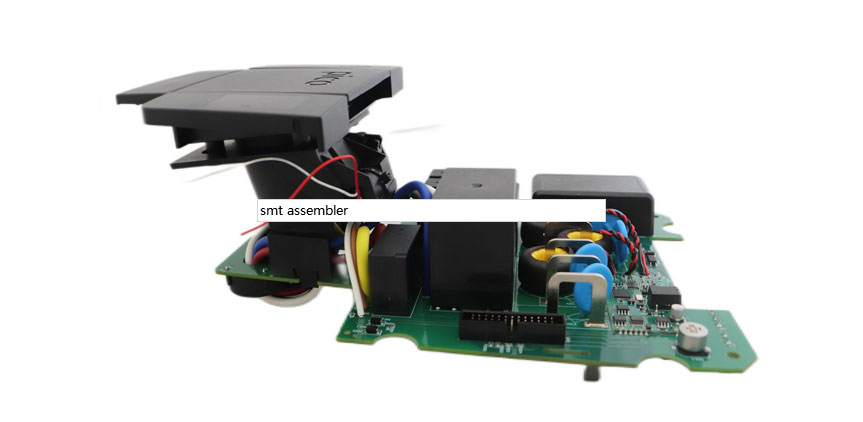

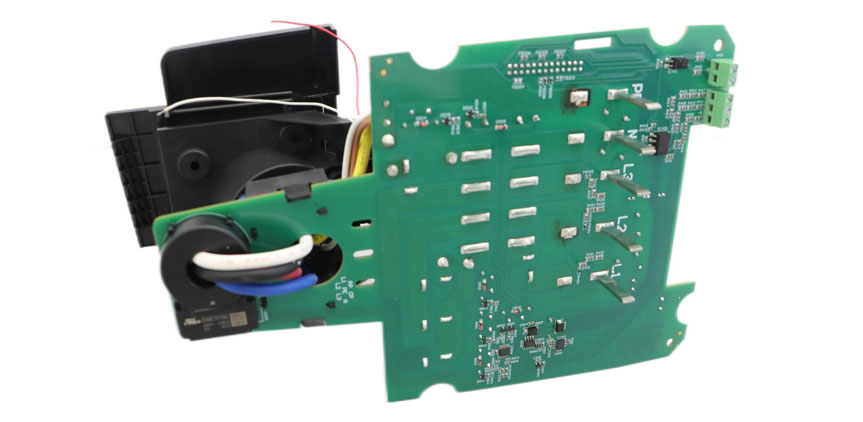

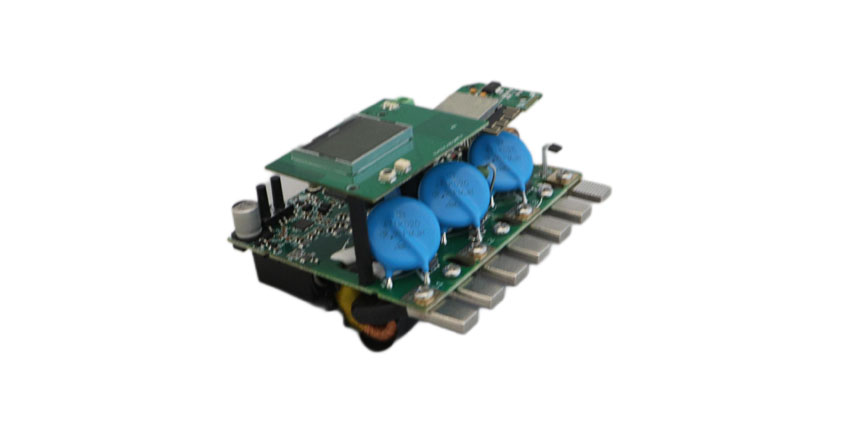

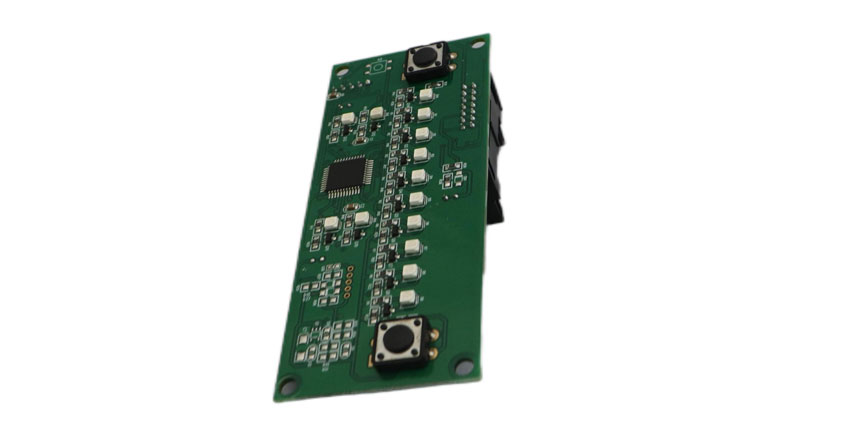

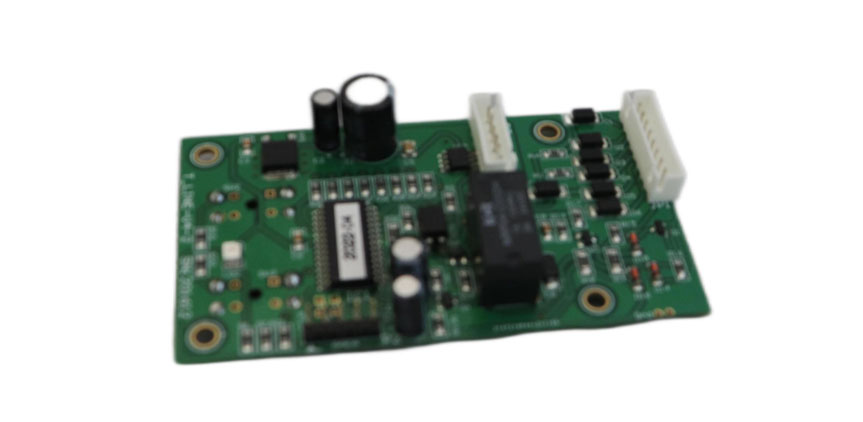

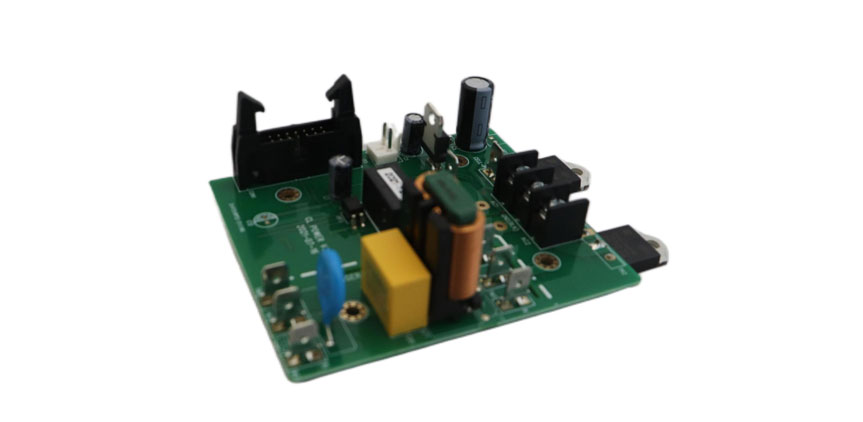

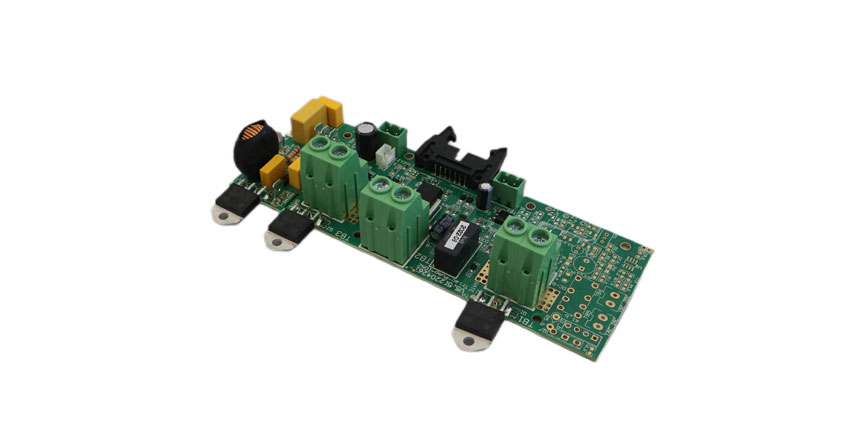

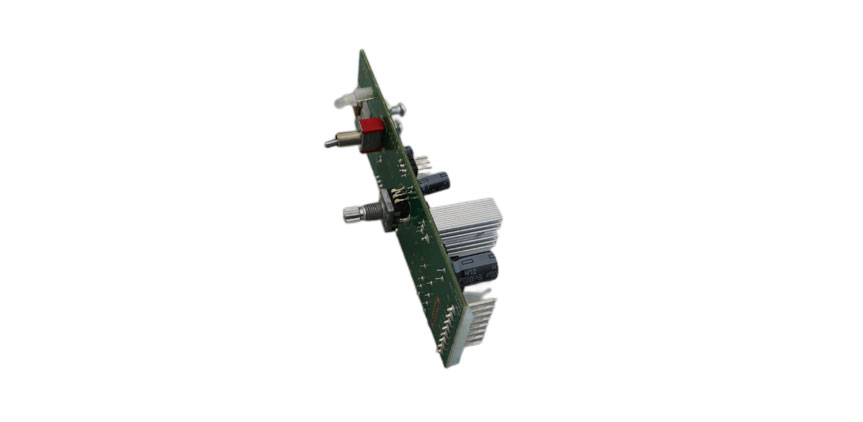

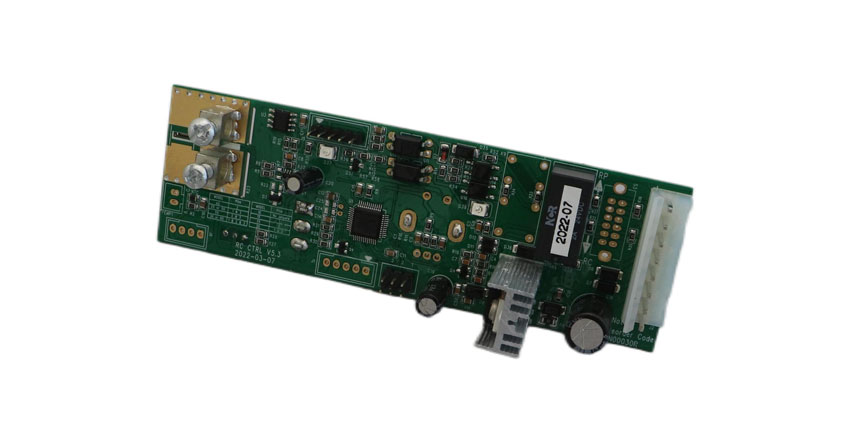

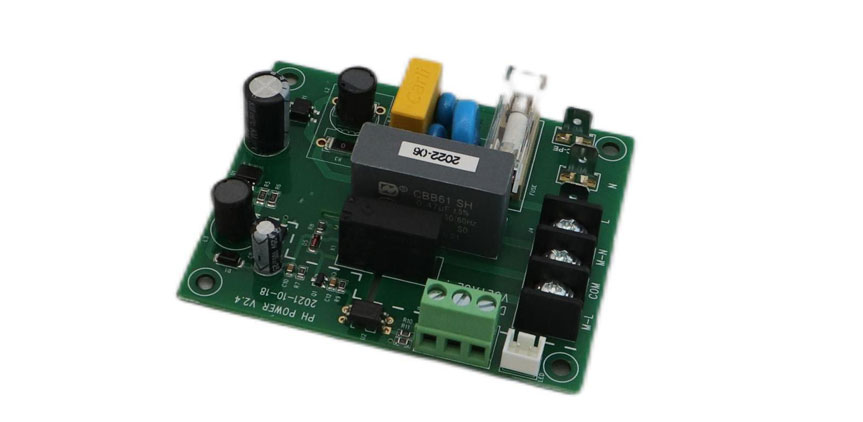

PCBA is a complete assembled board with electronic components. We apply surface mount technology and through-hole soldering technology solder the components onto the board. The components are soldered to the board can be SMD, through hole, UBGA, QFN, POP, leadless chips, connectors and terminals.

Preproducing engineering checking

Board cutting

Print inner layer

Eych inner layer

AOI

Layer up and bond

Drilling the PCB

Electroless copper deposition

Image teh outer layer

Plating

Etch the outter layer

AOI

Solder mask

Surface finish

Profile

Electrical test

Finial inspection

Packing

Yes, thanks for your update on the projects status,it’s good for me to make our order plan.

Your engineer check the files very carefully,thank you for it, it helps me a lot.

The goods arrived very well, the packing is good, thank you.

We've been worked with GreensTone for many years, there is no failure.

I reached out to GreensTone Electronics to manufacture the circuit boards. After a few discussions, Rebecca could see the community focus of the project and went above and beyond to reduce costs, ensure delivery and filmed elements of the production for educational purposes. Manufacturing offshore isn't as easy as it appears on the surface so it was invaluable to have Rebecca believe in the cause and be an ally in the production working toward the same goal.

Yes, thank you we received the 34x LC VMS TILE 1C REV A earlier this week. The assembly quality is very good.

Thank you for taking time to check it,you are very efficient.

Your engineer is very clever,thanks for the help to check the file's problem.