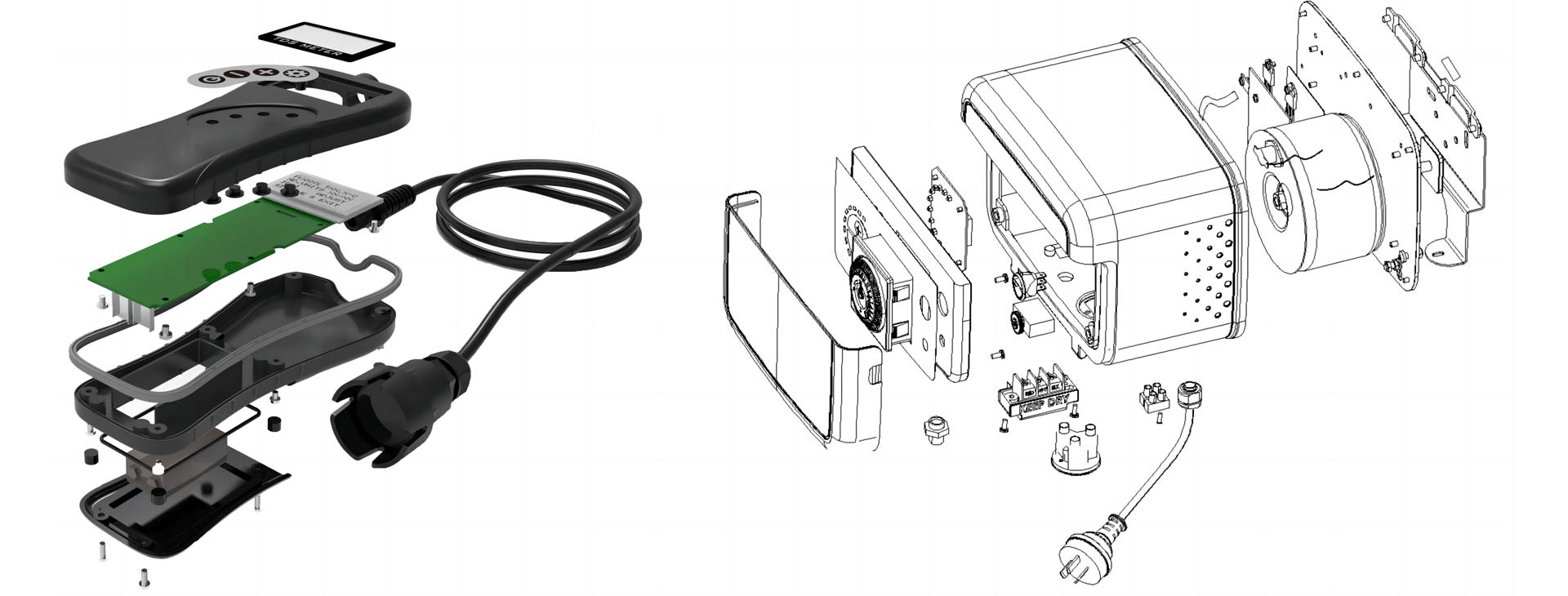

Production for swimming pool chlorinator

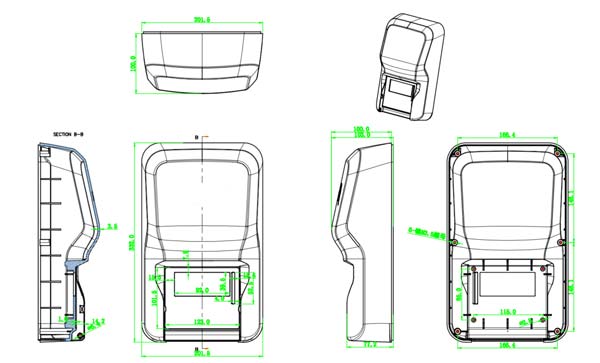

PCB manufacturing, components sourcing and give equvelent chips suggesting. Molding & Plastic Injection. Box build Assembly. Inspection Testing and Certification performance.

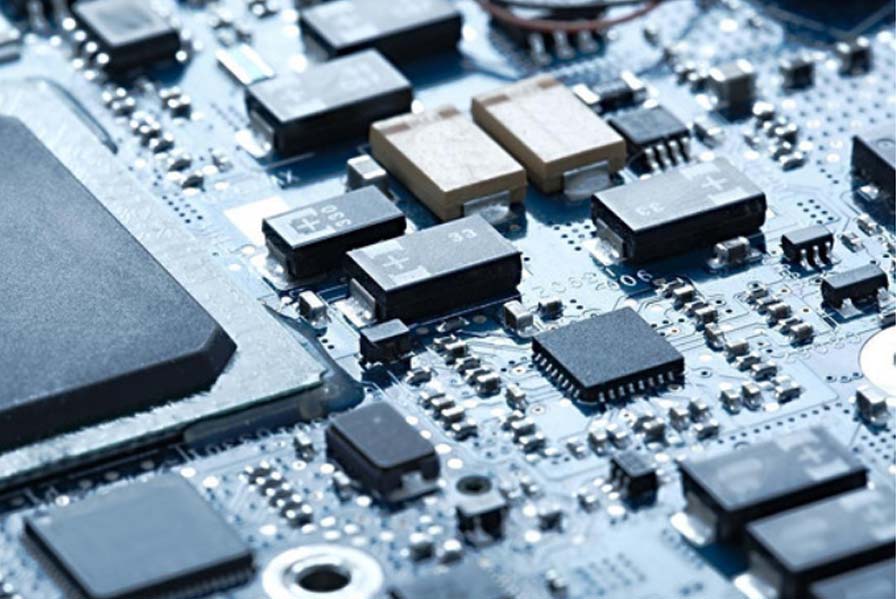

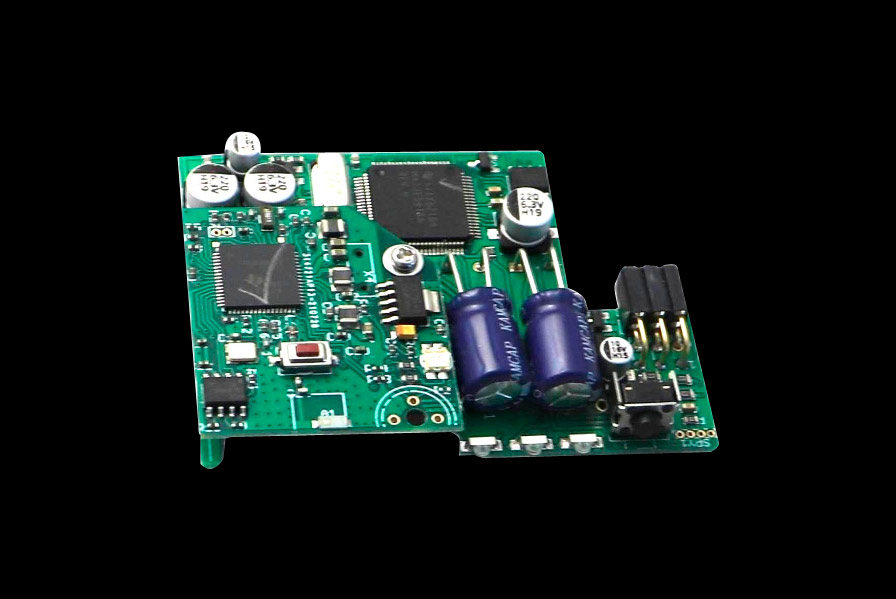

The chlorinator only took 6 months from research and development to mass production. From circuit boards, SMT, molds, injection molding, sheet metal, and integrated finished products assembly are all completed by self-operated factories to ensure the quality of each product.

Scope of contract

Design support, Board manufacturing, SMT mounting, parts procurement, PCB assembly, programming, inspection, Box build assembly, technical advice

Quantity: Over 100000pcs

China Heavy Copper PCB: Choose Professional Thick Copper PCB Manufacturer for Reliable Quality

Introduction to Heavy Copper PCB and GreenPCBA's Market PositionIn the field of high-power electronics, heavy copper PCB has become a core component supporting the stable operation of equipment. A...

China Heavy Copper PCB: Choose Professional Thick Copper PCB Manufacturer for Reliable Quality

Introduction to Heavy Copper PCB and GreenPCBA's Market PositionIn the field of high-power electronics, heavy copper PCB has become a core component supporting the stable operation of equipment. A...

GREENPCBA Facilitates Customer's Product to Successfully Obtain UL Certification, Demonstrating Strong R&D Capabilities

Recently, relying on its solid R&D technical strength and efficient customer collaboration mechanism, GREENPCBA has successfully assisted the [WATER TREATMENT EQUIPMENT] in completing the full-pro...

GREENPCBA Facilitates Customer's Product to Successfully Obtain UL Certification, Demonstrating Strong R&D Capabilities

Recently, relying on its solid R&D technical strength and efficient customer collaboration mechanism, GREENPCBA has successfully assisted the [WATER TREATMENT EQUIPMENT] in completing the full-pro...

China Electronic Manufacturing Services: Choose Professional EMS Provider for Quality Assurance

Trusted Electronics Manufacturing Services Provider with 12+ Years of ExpertiseIn the global electronics industry, China electronic manufacturing services have gained widespread recognition for their ...

China Electronic Manufacturing Services: Choose Professional EMS Provider for Quality Assurance

Trusted Electronics Manufacturing Services Provider with 12+ Years of ExpertiseIn the global electronics industry, China electronic manufacturing services have gained widespread recognition for their ...