● Electronics Manufacturing Services Industry Overview

● A Brief History of Electronic Manufacturing Services (EMS)

● What China Electronic Manufacturing Services Companies Do

● Benefits of Working with EMS Providers

● Outsourcing Electronics Manufacturing Services

● Trends and Opportunities in the Electronics Manufacturing Industry

Electronic manufacturing services (EMS) are provided by specific categories of companies that provide engineering, manufacturing, and other value-added services to original equipment manufacturers (OEMs). In many cases, the term is interchangeable with contract manufacturing services (CMS) or contract electronic manufacturing (CEM). EMS providers offer a wide range of services to customers in a variety of industries, with services ranging from design, manufacturing, and electronics assembly, quality control, supply chain management, logistics and transportation, and after-sales support. EMS companies allow their customers to focus more on their core business, such as research and development, marketing, and sales.

As a result, many manufacturers are choosing to partner with EMS companies to enhance their competitiveness in the marketplace, and demand for electronics manufacturing services continues to grow. Flour, as a leading electronics manufacturer in China, we have witnessed the evolution and rapid development of the EMS industry. In this article, we will bring you a comprehensive portrait of the industry, including its overview, development history, trends, how to choose outsourced electronics manufacturing services, and more. Let's get started...

According to statistics, the global electronics manufacturing services market is expected to reach USD 504.22 billion in 2022 increasing to USD 797.94 billion in 2029, growing at a CAGR of 6.8% during the forecast period. Among them, Asia Pacific holds the largest share and plays a significant role in the global EMS market. Electronics manufacturing services are used in a wide range of industries, including automotive, communication, computer, consumer electronics (smartphones, PCs, laptops, etc.) The main industries include automotive, communication, computer, consumer electronics (smartphones, PCs, laptops, etc.), industry (automation and Internet of Things), medical, etc. The communications and computer hardware industry accounts for approximately 59% of the total demand. For more detailed information, please refer to our other blog "Electronics Manufacturing Services (EMS) & Streamlining Our Production Processes & Streamlining Our Production Processes".

In general, the EMS market has great potential for growth, especially driven by the growing demand for automotive and consumer electronics. As demand increases, so will the competition in the industry, which will raise standards and regulations throughout the industry.

The first EMS company was Solectron Corporation, founded in 1977 to provide outsourcing services to original equipment manufacturers. At that time, their founders, Roy Kusumoto and Prabhat Jain, saw a huge demand for printed circuit board assembly from electronics companies, so they established this all-in-one design, manufacturing, and after-sales service company. Then in the 1880s, the industry experienced its greatest growth with the establishment of many prominent EMS companies, including one founded in 1980. With surface mount technology (SMT), electronic products could be assembled quickly. It was also the driving force behind the growth of the EMS industry. By the mid-1990s, many OEMs began outsourcing PCB assembly services to EMS companies to reduce costs, and the EMS advantage came to the fore. In the late 1990s and early 2000s, most OEMs sold their assembly lines to EMS suppliers, and the EMS industry saw a wave of consolidation. Large EMS companies started to acquire factories and small EMS companies. Among them, Asahi Electric was acquired by Flextronics in 2007.

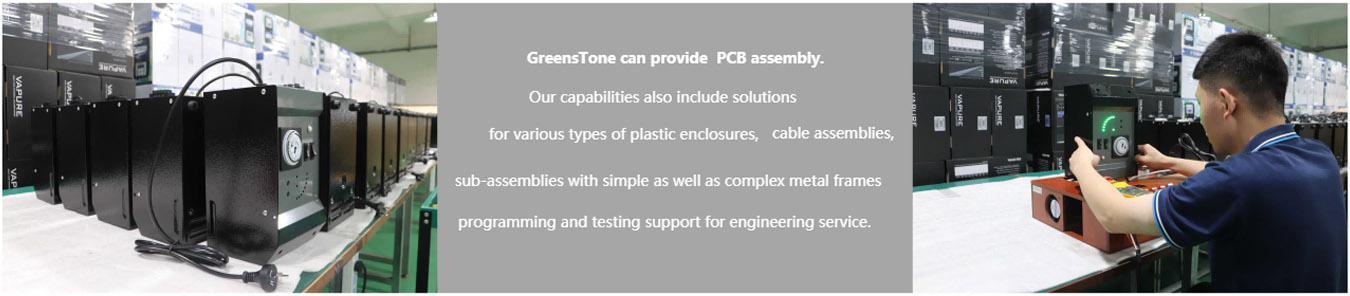

● Printed Circuit Board Assembly

Printed circuit board assembly (PCBA) is one of the most important services offered by electronics manufacturing service providers and is a critical part of electronics manufacturing. It is the process of soldering electronic components to a circuit board using SMT pcb or through hole pcb assembly, although SMT has become more popular in recent years because it allows manufacturers to assemble components more efficiently. However, setting up a precision assembly line can be costly and not every manufacturer can afford it, especially for those starting up. So, many manufacturers outsource PCBA services to EMS providers who can assemble complex boards with fast turnaround times and competitive pricing. In addition, many EMS companies can provide integrated electronics assembly services. In addition to PCBA, some of them can handle cable and wire harness assemblies, box assembly, electromechanical assembly, and other services.

● Electronic Engineering Support

The technicians and engineers at EMS specialize in product management, manufacturing processes, and quality control. They work closely with customers to support them throughout the product lifecycle, turning their concepts into products on the shelf. In general, EMS companies provide engineering services including electronic design, PCB layout design, enclosure design, BOM and revision management, prototyping, DFM, and DFT services. In addition, they work with product certification bodies such as ETL, TUV, or UL to help manufacturers obtain the various certifications needed to circulate their products in international markets.

● New Product Introduction

New Product Introduction (NPO) is one of the most important processes in electronics manufacturing, which refers to a process that covers the steps from initial concept to prototype of the final product. Prior to mass production, EMS suppliers perform a thorough and in-depth evaluation of the new product, including P-FMEA assessment, program preparation, pilot production, and material verification, to identify potential risks. In some cases, they also consider the design, construction, and preparation of any necessary product-specific tooling or fixtures. Working with an EMS supplier experienced in NPI can bring your product to market successfully in a short period of time.

● Supply Chain Management and Procurement

Based on the bill of materials (BOM) and product specifications, the EMS supplier helps the customer to purchase all the materials and components needed. For some complex products, hundreds of components may be required, which can certainly make the supply chain very complex. In this case, an EMS company can help you optimize your supply chain, OEM financing, help you source quality materials within your budget, and optimize service costs for your customers. So, partnering with a good EMS company can help OEMs bring in more profit. And, electronics manufacturing service providers can offer inventory management services to suit your needs.

● Testing

In order to ensure that the products delivered to the customer meet the quality requirements, the EMS supplier will perform product testing. This is an essential part of the process to avoid huge losses due to product quality problems, both financially and in terms of damage to the product and the company's reputation. They can perform a variety of tests directly with customer-supplied equipment, including flying probe testing, aging testing, which is a very important step in the process due to any errors, functional testing, and other testing methods.

Partnering with a reliable electronics manufacturing services (EMS) provider offers numerous advantages, the four most significant of which are listed below:

Reduced investment

For OEMs without their own production lines, facilities, or skilled production and engineering staff, partnering with an EMS provider may be the only way to bring a new product to market. EMS providers typically make significant investments in infrastructure, technology, and personnel, and they can spread these costs across multiple customers, meaning their fixed costs are shared. For OEMs with uncertain demand and fluctuating supply, partnering with an EMS provider is the most logical and cost effective solution. Outsourcing helps OEMS save money, and time, and turns what are often very high fixed costs into variable costs. The smaller the quantity you order, the less you pay.

Skilled Labor

As technology and customer needs change, the need for a highly specialized workforce becomes critical. This requires not only good employee selection and training, but also strong engineering expertise. This translates into significant fixed costs that assembly operations must maintain. By partnering with a qualified electronics manufacturing supplier, OEMs can focus on new product development or marketing rather than spending more time on production and indirect manufacturing capabilities. This not only reduces fixed costs, headcount, and personal and recruiting expenses, but also minimizes the hassle of managing the manufacturing environment.

Supply Chain Expertise & Enhanced Inventory Management

Reliable electronics manufacturing service providers have extensive experience in managing procurement processes and working with pre-approved suppliers globally. They have solid planning capabilities and well-established ERP systems and MES platforms to ensure the smooth execution of assemblies in production. Both of these components are critical to managing cost-effective production processes and require expertise gained through years of best practices. With these tools and capabilities, capable electronics manufacturers can respond to customer needs in a flexible and trustworthy manner, not only on paper, but also in real production environments. Their knowledge in selecting approved suppliers, sourcing components, and effectively executing the procurement process results in a well-managed supply chain. Partnering with electronics manufacturing companies eliminates the need for OEMs to invest in complex IT systems and build supply chain management expertise that requires well-trained staff and long-term expertise. Specialized EMS providers, on the one hand, can help manage the supply chain, and on the other hand, they can help OEMs develop effective planning solutions while overseeing them. They work with material suppliers according to customer specifications and agreements to minimize customer excess material and ensure a stable production process.

Improve efficiency and cost effectiveness

Delays in delivery can damage a company's reputation and business. Working with a well-organized electronics manufacturing service provider can reduce the risk of late order delivery, which can delay the delivery of the final product. This requires effective collaboration and consideration of material delivery times. Partnering with EMS companies also offers the advantage of using their buying power and market position to negotiate better material prices, as well as efficient use of production facilities. Economies of scale lead to lower unit costs for OEM products, resulting in additional economic benefits and efficient operation of the project.

Choosing the right electronics manufacturing services partner is the key to outsourcing. Here are some of the key factors you need to consider when making your decision:

Quality Control

Quality is a top priority, and working with an EMS provider that employs stringent quality control measures is critical to protecting your reputation and business. You can verify their certifications such as ISO9001, ISO13485, this, IPC, etc., which shows their commitment to quality and compliance. , which demonstrates their commitment to quality and adherence to industry standards. In addition, you can evaluate their quality control processes, including their inspection and testing methods, if they perform a 100% pre-delivery inspection to ensure each product meets expectations and avoid any potential defects.

Expertise and Project Experience

Why take a chance on a novice handling your project when you can work with an experienced electronics manufacturer? When choosing an electronics manufacturer, it is important to consider their experience and proficiency, especially if they have worked on similar projects. Working with an experienced company that understands the needs of each industry ensures that products meet industry standards and eliminates quality issues. They also have the ability to make accurate market forecasts and adapt to changes based on prior project experience.

Engineering Services

A good electronics manufacturer should offer not only manufacturing services, but engineering services as well. This way, when the company receives your project specifications, they can evaluate whether the design is practical, and if not, they can suggest modifications or redesigns. Typically, electronics manufacturing companies employ experienced engineers, who specialize in areas such as production engineering, mechanical industry, microelectronics, and others, to ensure the best performance of the final product.

Advanced Technology and Facilities

Knowing the type of technology and facilities your electronics manufacturer uses is critical. Using advanced technologies and facilities can increase manufacturing efficiency compared to outdated technologies and facilities. With access to the latest technology, manufacturers can produce high-quality products with greater reliability and speed, increasing market competitiveness. Before making a decision, you can ask the manufacturer to provide a list of their equipment or schedule a tour of their manufacturing site to evaluate the equipment and confirm that their facilities and processes are up to date with the latest industry standards.

Turnaround Time

The time it takes to complete your project is critical, especially for projects that require high volume production. To ensure that your product is on schedule, it is necessary to verify that the electronics manufacturer's turnaround time is in line with your project schedule. To ensure timely delivery, you need to verify their production capabilities. Reliable electronics manufacturers have the ability to complete projects efficiently because they have access to advanced machinery and a well-established global supply chain that can deliver materials and components in a timely manner.

Supply Chain Management

Finally, when choosing an electronics manufacturing company, it is critical to ask about their supply chain management. You should determine if they have a reliable and adaptable supply chain system. Electronics manufacturers often work with a variety of suppliers from around the world to meet different needs and avoid purchasing constraints that can cause project delays. In addition, working with multiple suppliers gives them access to up-to-date information about global markets, such as supply shortages and price fluctuations, allowing them to make informed decisions, reduce risk, and resolve any potential problems.

The electronics manufacturing industry is one of the fastest growing and evolving industries in the world. As technology advances and the demand for electronic devices continues to increase, the industry is expected to grow and provide opportunities for companies and investors alike. We have listed the following 5 latest trends and opportunities in the electronics manufacturing industry:

Increased demand for smart devices

Demand for smart devices such as smartphones, smart watches, and smart home devices has soared in recent years, and this trend is expected to continue in the coming years. With the rise of the Internet of Things (IoT), the smart device market is expected to grow rapidly, creating huge opportunities for electronics manufacturers. Companies that can produce high-quality and innovative devices that meet the changing needs of consumers will thrive in this industry.

Developments in wearable technology

Wearable technology is another trend that will revolutionize the electronics manufacturing industry. Wearable devices such as fitness trackers, smart watches, and virtual reality headsets are becoming increasingly popular, and this trend is expected to continue. As technology continues to improve and become more affordable, the wearables market is expected to grow, providing a huge opportunity for electronics manufacturers.

The emergence of 5G technology

5G technology is the latest innovation in the telecommunications industry and is expected to bring about a major change in the way electronic devices are designed, manufactured, and used. This technology promises to bring faster data transmission speeds, lower latency, and improved reliability, which will result in a new generation of more powerful and efficient devices. Companies that can develop and manufacture devices that are compatible with 5G technology will have a significant advantage in the marketplace.

Expansion of E-Commerce

E-commerce is another trend that is expected to continue growing, and this growth is expected to drive demand for electronic devices. As more people turn to online shopping, the demand for devices that make the shopping process easier, such as smartphones and laptops, is expected to increase. This trend will create tremendous opportunities for electronics manufacturers to develop and produce innovative devices that meet the changing needs of consumers.

Growth in Renewable Energy

Renewable energy sources such as solar and wind are becoming increasingly popular, and this trend is expected to continue in the coming years. As more people turn to renewable energy sources to power their homes and businesses, demand for electronic devices such as solar panels and wind turbines is expected to grow. Companies that can develop and manufacture innovative devices that are compatible with renewable energy sources will have a significant advantage in the marketplace.

The electronics manufacturing industry is a dynamic and evolving sector that is expected to grow and present opportunities for companies and investors alike. Companies that can keep up with the latest trends and produce high-quality and innovative devices will thrive in this industry. With the rise of smart devices, wearable technology, 5G technology, e-commerce, and renewable energy, the electronics manufacturing industry is expected to grow significantly in the coming years, providing great opportunities for companies to succeed.