When talking about electronics manufacturing, the acronyms SMD and SMT are often used. on the surface, they appear to be almost identical - surface mount devices (SMD) and surface mount technology (SMT) are separated by just one letter. In reality, however, SMD and SMT refer to completely different aspects of the production process. SMT refers to innovative techniques for efficiently mounting electronic components onto circuit boards. These modern assembly methods allow for smaller, faster, and more streamlined production. SMDs, on the other hand, are the actual individual parts and assemblies that are mounted on a circuit board. These surface mount devices are mounted to the circuit according to the specific SMT process used. The key difference is that SMT describes the entire process while SMD describes the physical device. In this blog, we'll cover each in detail and highlight the differences between the two terms. Let's start with what it means.

SMD (or Surface Mount Device) stands for an electronic component designed to be soldered directly to the top layer of a printed circuit board surface instead of using the old-fashioned through-hole connection. This innovation allows smaller components to still provide full functionality. By mounting more circuits onto a compact board without drilling, SMDs enable faster and more cost-effective PCB production. In addition, the surface tension of the molten solder automatically corrects small errors in SMD placement. These devices also reduce unwanted RF interference and improve high frequency performance. Because of their small size, lack of leads, and suitability for PCB surface mounting, SMDs are less costly than alternatives that require drilling mounting holes.

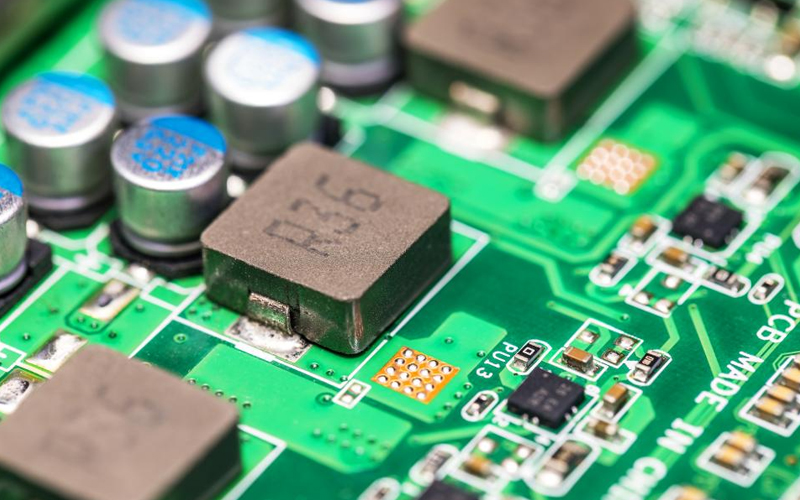

Here are some of the main types of SMD electronic components:

Resistors - used to limit or control the current in a circuit. Common types of SMD resistors are chip, metal film and thick film.

Capacitors - store charge and regulate voltage in a circuit. Popular SMD capacitors include ceramic, tantalum and electrolytic capacitors.

Inductors - coils used to store energy in a magnetic field. smd inductors include wirewound, multilayer ceramic chips, and ferrite bead types.

Transistor - a semiconductor that amplifies or switches electronic signals and power. Common SMD transistors are MOSFETs, BJTs, and IGBTs.

Diodes - they enable current to pass in a single direction. smd diodes include zener diodes, schottky diodes, and light emitting diodes.

Integrated circuits - Prefabricated circuits that perform specialized functions. Types include microprocessors, amplifiers, regulators, and GPUs.

SMD crystals come in a variety of shapes and sizes.

LED - Light Emitting Diode that produces illumination. Available in low power indicator types or high power illumination arrays.

Connectors - Allow for removable electrical connections. Examples include USB, HDMI, and board-to-board connectors.

The SMT assembly process involves four key steps:

Printing - The SMT machine aligns the stencil on the PCB and uses a squeegee to apply solder paste through the holes in the stencil to the PCB's pads.

Mounting - the pick-and-place machine precisely positions the tiny SMD components on the PCB and uses solder paste to temporarily adhere them.

Reflow Soldering - This involves heating the solder paste to a semi-liquid state, which needs to be completely melted and solidified to ensure a strong and durable soldered connection. With precise temperature control and even heat distribution, reflow soldering is commonly used in surface mount assembly to reliably solder precision components such as BGAs and QFNs.

Testing and Inspection - After assembly, the manufacturer performs a variety of inspections to verify the quality of the soldering, checking for proper alignment, solder bridges, shorts, and more. The process combines manual inspection, AOI and various other methods.

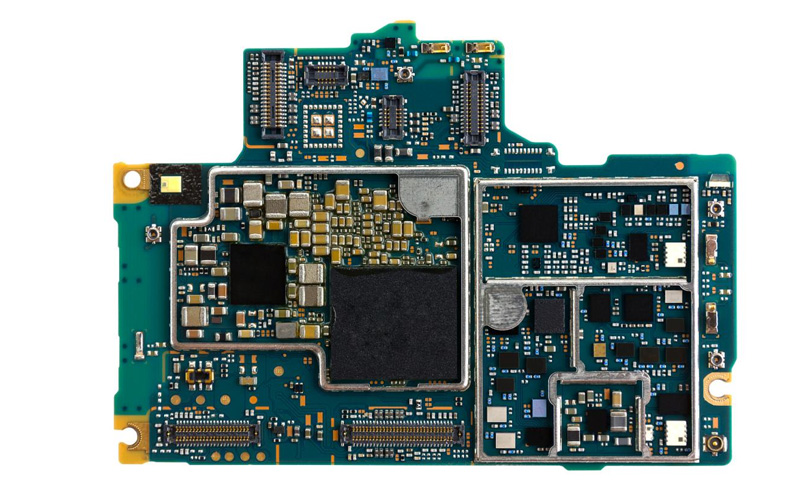

Higher component density: SMT technology allows components to be placed on both sides of the board, maximizing the use of available space and allowing for higher component density.

Increased speed and efficiency: Automated SMT PCB assembly allows for fast and efficient production processes due to its high level of automation. Modern placement machines can place thousands of components per hour, significantly speeding up the assembly process.

Cost Effectiveness: While the initial setup costs of SMT PCB assembly can be high, high speed, automated production and reduced material costs for smaller components often result in overall cost savings, especially for high volume production.

Design Flexibility: Surface mount assemblies offer greater design flexibility, allowing engineers to create innovative and complex circuit designs that may not be possible or practical with through-hole components.

Although SMT and SMD involve different concepts, they work hand-in-hand to enable state-of-the-art electronics manufacturing. Looking back, the decline of through-hole DIP components was due in part to the limitations of hand soldering. This spurred the rise of automated mounters. While manual soldering was once sufficient for basic SMD assembly, bonderized machines have made this method obsolete. the convergence of SMT and SMD offers several benefits:

SMT Optimizes High-Volume SMD Assembly

Automated production models are designed to minimize PCB assembly costs, and SMDs offer a cost-effective solution here. SMT systems allow thousands of miniature SMDs to be quickly placed on a board in the shortest possible time.

SMDs Maximize Board Capacity

The compact size of SMDs allows more circuits to be packaged on the board, and SMT utilizes this advantage by densely mounting SMDs.

SMDs Enhance Process Reliability

SMDs utilize lead-free soldering. SMDs utilize lead-free soldering, which helps PCBA companies reduce assembly failures and improve the overall robustness of the SMT process.