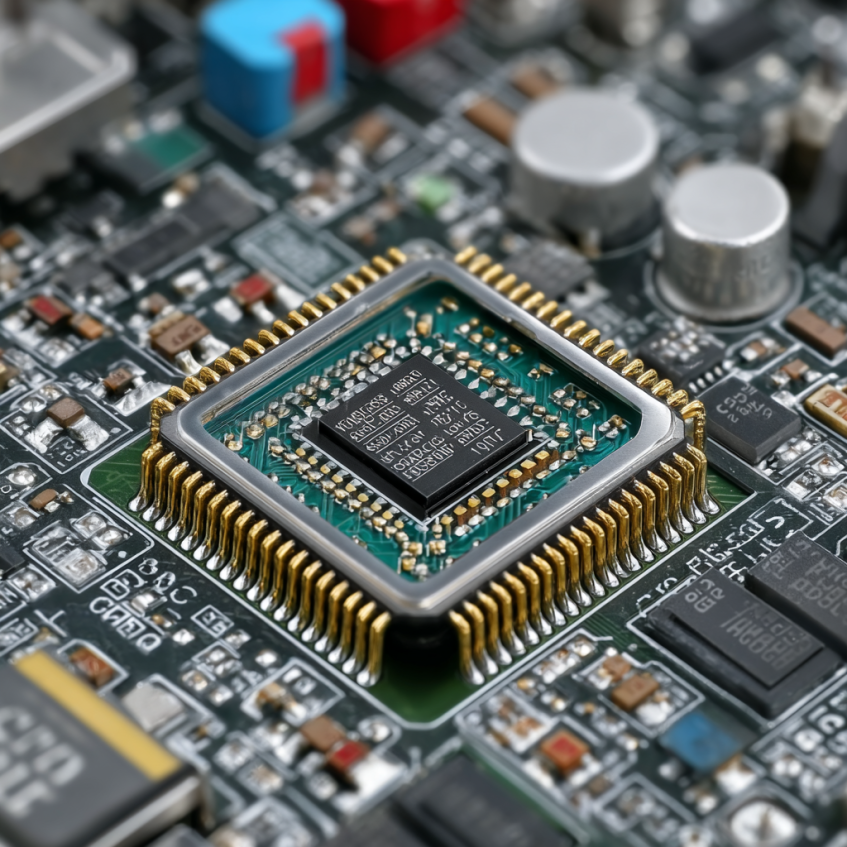

When it comes to modern electronic devices, Ball Grid Array (BGA) technology plays a critical role in achieving compactness, high performance, and multi-layer connectivity. Choosing a reliable BGA PCB assembly service in China is essential for businesses that require consistent quality, efficiency, and cost-effectiveness in their production.

China is home to hundreds of PCB assembly manufacturers, but not all are created equal. In this guide, we will explore what to look for in a China BGA PCB assembly service provider and why GreensTone stands out as a trusted partner in this highly specialized field.

BGA (Ball Grid Array) is a surface-mount packaging method used to permanently mount devices such as microprocessors onto printed circuit boards. BGA offers advantages like:

Higher pin density and connectivity

Better thermal and electrical performance

Compact design for space-limited applications

However, assembling BGA components requires precise equipment, advanced inspection capabilities, and experienced engineers. Mistakes in BGA assembly—such as misalignment or cold solder joints—can lead to performance failure or complete board rejection. That’s why choosing the right assembly partner is critical.

Look for a manufacturer with proven experience in handling BGA components, especially fine-pitch BGAs, µBGAs, and lead-free assemblies. GreensTone has over 15 years of experience in advanced PCB assembly, including HDI, multilayer, and BGA technologies.

Since BGA solder joints are hidden under the chip, traditional inspection methods like AOI are not sufficient. You’ll want a provider that offers:

X-ray inspection (essential for BGA quality assurance)

Functional testing

ICT (In-Circuit Testing)

GreensTone uses high-resolution X-ray inspection for every BGA-mounted board to detect internal voids, cold joints, or bridging defects.

Precision assembly like BGA requires cleanroom environments to reduce contamination and improve yield. GreensTone’s facilities are ISO 9001 and ISO 13485 certified, with strict quality control at every stage, from incoming material inspection to final packaging.

A strong engineering team can review your Gerber files, BOMs, and stencil designs to provide valuable Design for Manufacturability (DFM) feedback. This reduces production errors and speeds up turnaround time.

GreensTone offers free engineering file checking and pre-assembly consultation, helping you optimize your design before mass production.

Time-to-market is key. Make sure your BGA PCB assembly partner offers both prototype and volume production options, along with fast lead times.

GreensTone provides:

| Service Type | Turnaround Time |

|---|---|

| Prototype (1–10 pcs) | As fast as 3–5 days |

| Small batch | 5–7 working days |

| Mass production | 10–15 working days |

This flexibility supports both startups and established OEMs.

GreensTone has positioned itself as a full-service PCB manufacturing and assembly company based in China, offering one-stop solutions from PCB fabrication to final assembly and testing.

Turnkey PCB assembly service (including component sourcing, fabrication, and testing)

Support for low to medium volume orders with low MOQ

Strong focus on high-reliability industries including medical devices, automotive, and industrial controls

BGA rework capability for fast correction of defective parts

Competitive pricing with no compromise on quality

Whether you are looking to outsource a complex multilayer board with BGAs or just need a few quick-turn prototypes, GreensTone has the infrastructure and expertise to meet your needs.

Starting your BGA PCB assembly project with GreensTone is simple:

Submit your files (Gerber, BOM, Pick and Place, etc.) via their PCB assembly page

Receive a fast quote within 24 hours

Get engineering file checks and feedback before production

Track production in real-time with dedicated customer support

Receive fully tested, quality-inspected products

Choosing the right China BGA PCB assembly service is not just about price—it's about reliability, process control, technical support, and long-term partnership. GreensTone combines these elements with professional service, robust capabilities, and a dedication to customer satisfaction.

If you’re looking for a dependable and experienced partner for your BGA assembly projects, GreensTone is a name you can trust.