Recently, relying on its solid R&D technical strength and efficient customer collaboration mechanism, GREENPCBA has successfully assisted the [WATER TREATMENT EQUIPMENT] in completing the full-process testing and review for UL certification, securing the authoritative certification certificate. The smooth acquisition of this certification indicates that the product fully meets the North American market access requirements in terms of safety performance and quality standards, laying a solid foundation for the customer to expand overseas markets.

Since the project kick-off, GREENPCBA's R&D team has maintained in-depth collaboration with the customer, set up a special technical task force, and participated in the technical preparation, scheme optimization and testing breakthrough of the product certification throughout the process. In response to the stringent safety standards of UL certification, the R&D team first conducted a comprehensive disassembly and analysis of the product's core design, and formulated targeted technical optimization plans focusing on three core assessment dimensions: circuit safety protection, material heat resistance and flame retardancy, and structural stability.

During the early scheme design phase, the R&D team accurately matched the application scenario requirements of the customer's product, selected high-reliability insulating materials and flame-retardant components, optimized the circuit layout, and added overcurrent and overtemperature protection modules to eliminate potential safety hazards from the source.

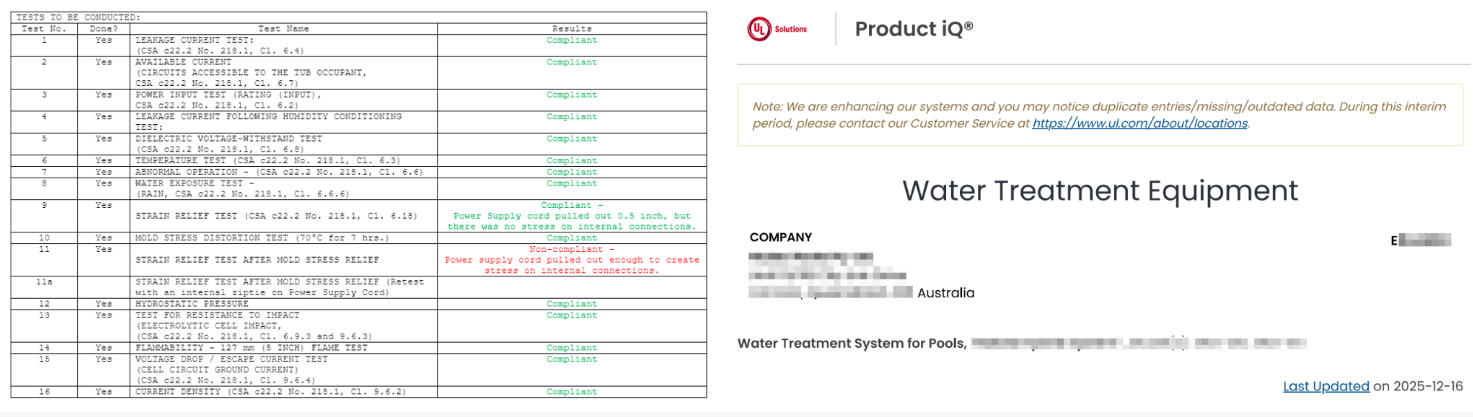

Upon receiving the test items feedback from the UL laboratory, the R&D team promptly organized relevant members to analyze the causes, explore solutions, and carried out rectifications. The re-tested product after rectification met and exceeded the UL certification standards.

"Successfully obtaining the UL certification in collaboration with the customer is not only the result of mutual technical synergy but also a practical test of GREENPCBA's R&D capabilities," said the R&D director of GREENPCBA. "We have always been customer demand-oriented, integrating international certification standards into the entire product R&D process. By proactively identifying risks and responding to problems quickly, we help customers shorten the certification cycle, reduce testing costs, and fully support their overseas market strategies."

As a professional provider of PCBA/ODM/EMS and full turnkey contract manufacturing services, GREENPCBA has always focused on technological innovation and quality upgrading, accumulating rich experience in electronic circuit design, component selection, and reliability testing. Moving forward, the company will continue to deepen technical cooperation with global customers, and with more high-quality R&D services, help more customers' products successfully obtain international authoritative certifications and gain a competitive edge in the market.