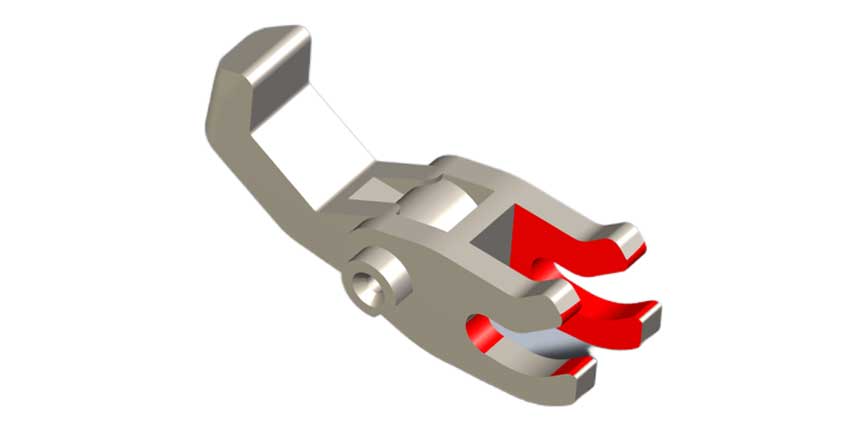

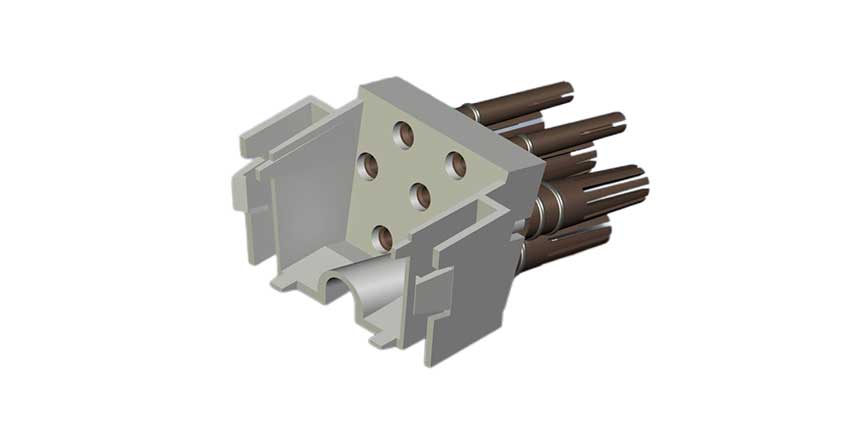

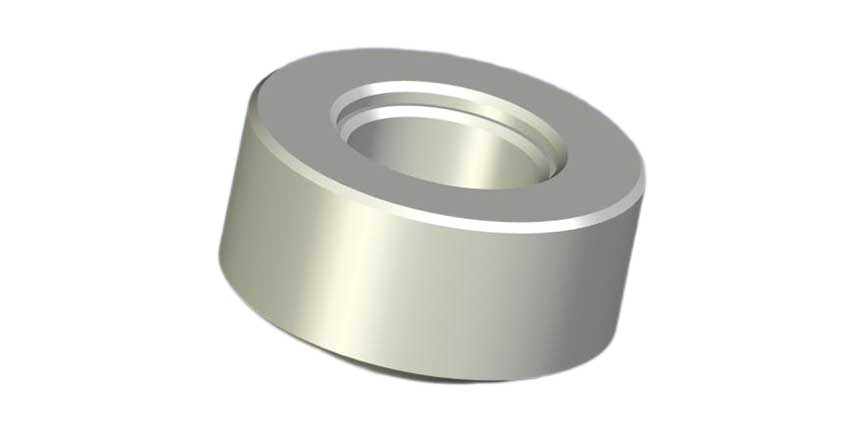

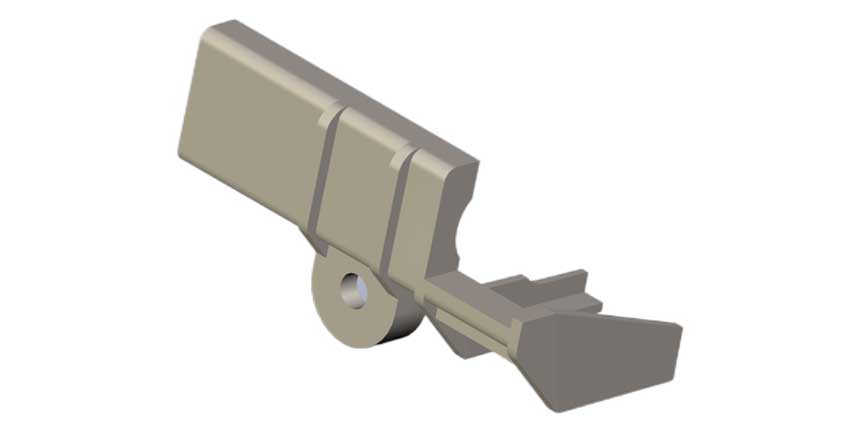

Sheet metal is used to make objects of various thicknesses, from very thin sheet metal to sheet metal with a thickness greater than 6mm. Sheet metal fabrication is a subtractive process that forms metal sheets to the desired shape by using a variety of manufacturing methods.

Sheet metal is usually used for applications like brackets and enclosures as It is featured with high accuracy and durability. There are many materials workable for sheet metal processing, such as steel, copper, aluminum, and so on.

GreensTone provides one-stop sheet metal fabrication services covering China custom sheet metal bending, laser cutting, welding, finishing, powder coating, and assembly. We can supply metal parts from prototypes to high-volume production runs and everything in between.

Wide Range of Materials

Choose from a variety of sheet metals across a wide range of strength, conductivity, weight, and corrosion-resistance.

Custom Surface Finishes

Select from a variety of finishes, including anodizing, plating, powder coating, and painting.

Fast Turnaround

Combining the latest cutting, bending and punching with automated technologies, GreensTone provides quick quotes and completed parts in as fast as 3-5 business days.

Durability

Sheet metal processes produce highly durable parts well-suited for both functional prototypes and end-use production.

Scalable Volume

All sheet metal parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype up to 100,000 production parts.

Cost Saving

Low investment in tooling and preparation costs, economical for metal sheet parts like bracket, chasis.

Material | Process | Surface finishes | Tolerance |

Aluminum 5052, Aluminum 6061, copper 101, copper 260, copper C110, stainless steel 301, stainless steel 304, stainless steel 316/316L, steel, law carbon | Laser cutting and bending | Bead blast, Anodized, Bead Blasting + Anodizing color or clear, Powder Coat, Chem Film | Cutting feature +/-0.2mm Bend angle +/-1.0° Bend to edge +/-0.254mm |

Yes, thanks for your update on the projects status,it’s good for me to make our order plan.

Your engineer check the files very carefully,thank you for it, it helps me a lot.

The goods arrived very well, the packing is good, thank you.

We've been worked with GreensTone for many years, there is no failure.

I reached out to GreensTone Electronics to manufacture the circuit boards. After a few discussions, Rebecca could see the community focus of the project and went above and beyond to reduce costs, ensure delivery and filmed elements of the production for educational purposes. Manufacturing offshore isn't as easy as it appears on the surface so it was invaluable to have Rebecca believe in the cause and be an ally in the production working toward the same goal.

Yes, thank you we received the 34x LC VMS TILE 1C REV A earlier this week. The assembly quality is very good.

Thank you for taking time to check it,you are very efficient.

Your engineer is very clever,thanks for the help to check the file's problem.

China Heavy Copper PCB: Choose Professional Thick Copper PCB Manufacturer for Reliable Quality

Introduction to Heavy Copper PCB and GreenPCBA's Market PositionIn the field of high-power electronics, heavy copper PCB has become a core component supporting the stable operation of equipment. A...

China Heavy Copper PCB: Choose Professional Thick Copper PCB Manufacturer for Reliable Quality

Introduction to Heavy Copper PCB and GreenPCBA's Market PositionIn the field of high-power electronics, heavy copper PCB has become a core component supporting the stable operation of equipment. A...

GREENPCBA Facilitates Customer's Product to Successfully Obtain UL Certification, Demonstrating Strong R&D Capabilities

Recently, relying on its solid R&D technical strength and efficient customer collaboration mechanism, GREENPCBA has successfully assisted the [WATER TREATMENT EQUIPMENT] in completing the full-pro...

GREENPCBA Facilitates Customer's Product to Successfully Obtain UL Certification, Demonstrating Strong R&D Capabilities

Recently, relying on its solid R&D technical strength and efficient customer collaboration mechanism, GREENPCBA has successfully assisted the [WATER TREATMENT EQUIPMENT] in completing the full-pro...

China Electronic Manufacturing Services: Choose Professional EMS Provider for Quality Assurance

Trusted Electronics Manufacturing Services Provider with 12+ Years of ExpertiseIn the global electronics industry, China electronic manufacturing services have gained widespread recognition for their ...

China Electronic Manufacturing Services: Choose Professional EMS Provider for Quality Assurance

Trusted Electronics Manufacturing Services Provider with 12+ Years of ExpertiseIn the global electronics industry, China electronic manufacturing services have gained widespread recognition for their ...