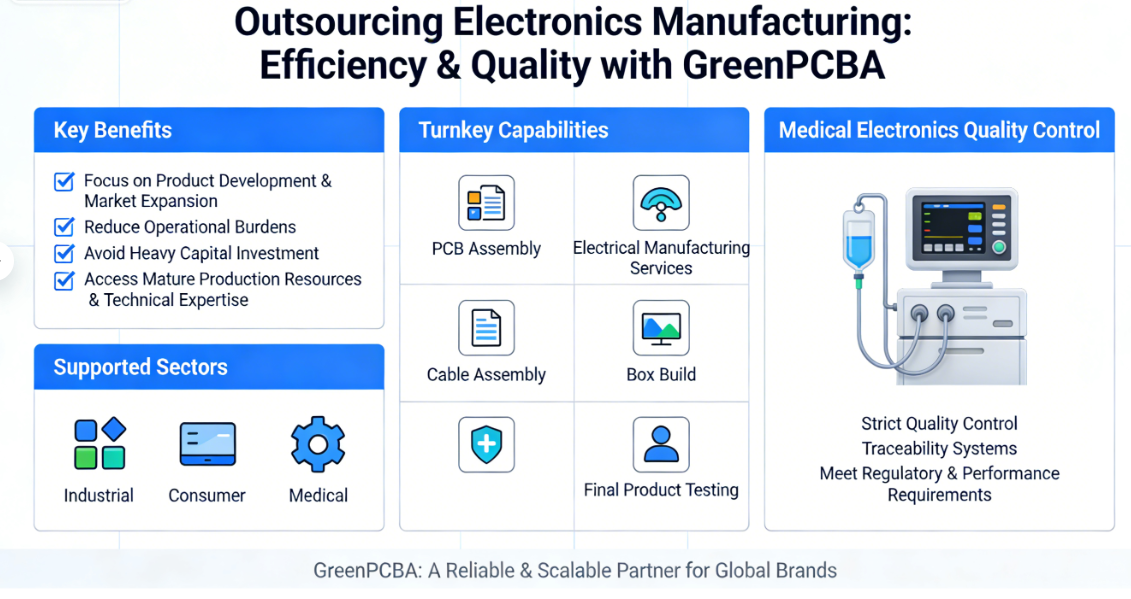

Outsourcing electronics manufacturing allows companies to focus on product development, brand building, and market expansion while significantly reducing operational burdens. By partnering with a professional electronic manufacturing services company in China, businesses can avoid heavy capital investment in facilities and equipment, lower labor and procurement costs, and gain access to mature production resources and experienced engineering teams. This approach improves manufacturing efficiency, enhances supply chain flexibility, and enables faster response to changing market demands.

GreenPCBA operates as a full-service electronics manufacturing services provider, delivering complete turnkey solutions that include PCB assembly, electrical manufacturing services, component sourcing, cable assembly, box build, and final product testing. By managing every stage of the production process under one roof, GreenPCBA helps customers reduce coordination risks, improve cost control, and maintain consistent quality. These turnkey capabilities support both low-volume prototyping and stable mass production.

As a professional electronic manufacturing services company, GreenPCBA supports customers across industrial, consumer, and medical sectors worldwide. In medical electronics assembly projects, strict quality control systems, traceability management, and multi-level testing are applied to meet regulatory and performance requirements. This makes outsourcing electronics manufacturing a reliable, scalable, and long-term strategy for global brands seeking high-quality and dependable manufacturing partners.